top of page

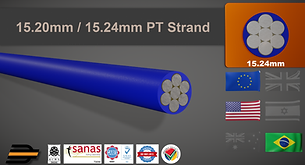

PLASTIC SHEATHED STRAND FOR POST-TENSIONING

Strand of all sizes and grades may be plastic sheathed in order to conform to the recommendations of the Fédération Internationale de la Précontrainte (F.I.P.) and the US Post Tensioning Institute (P.T.I.), or to any other standard.

This served to protect all seven wires, including the king wire. Corrosion resistant high temperature grease, or low slump paraffin wax, is then applied to fill all the voids between

wires, and to coat the strand with a protective layer,

usually 0,38mm at the outer wire crowns. High density polyethylene or polypropylene, is then extruded over

the greased strand with thickness to specification

or customer requirements.

_edited.png)

_edited.png)

GALVANISED PC STRAND

For some applications, such as maritime environments, particularly corrosive conditions may be encountered. Haggie's galvanised PC strand provides the additional protection required, and can be manufactured to customer requirements. Strand manufactured for drawn-galvanised wire is offered with the same mechanical and physical properties as bright strand, with no reduction in strength.

The fatigue requirements of all national and international specifications have been met. Strand manufactured from hot dip galvanised wire is also available. A range of zinc coating weights to suit customer requirements can be supplied.

_edited.png)

PC WIRE

Haggie produces PC wire on three modern low relaxation production lines. Finishes available are plain or indented. In addition to the wire sizes and grades listed below, other special grades are available on request.

COMPACT STRAND

DyForm or Compact Strands is a stranding configuration with concentric strands in which each layer is passed through a compacting die to reduce the diameter by approximately 10%.

Compacted prestressing 7-wire strands are where high strength is mandatory. These strands are primarily used in prestressed concrete applications. They play a crucial role in preloaded prefabricated parts, bridge construction, rock anchors in underground mining, large vessel containers, and hoisting technology for lifting heavy loads.

LINTEL

Lintel wire, also known as crimped wire, is a type of wire used for structural support and crack control in lintels and other precast products. It is manufactured from hard drawn wire and plays a crucial role in reinforcing lintels, which are horizontal beams or supports that span openings in walls or between vertical supports.

Haggie PC strand is suitable for stay cables and conforms to the

requirements of the F.I.B and P.T.I recommendations for Stay Cables.

The routine control of process parameters during manufacture, particularly

with regard to diameter, allows for bridge designers to bundle Haggie strand with confidence. Where individual strand sheathing is required, the Scaw plastication line

is capable of applying polymer sheathing in any profile at close thickness tolerances,

with prior application of a high temperature low slump grease or other corrosion inhibitors, such as paraffin wax. Fatigue endurance exceeds 2 million cycles at the special test conditions required for strand stay cables.

STRAND FOR STAY CABLE BRIDGES

.png)

bottom of page

.png)